With Diagrams to Build One

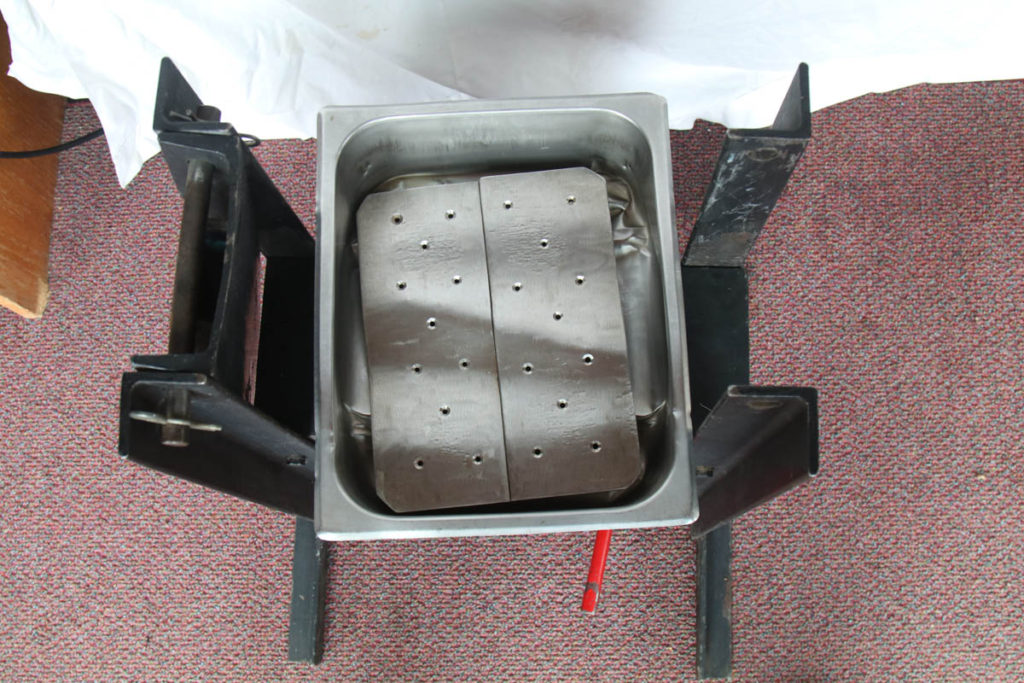

I currently have two tincture presses. The one featured here is quite large and heavy. I have had it for over 20 years and it still functions well. A few parts needed to be altered and fabricated, mainly the accessories such as the pans, steel plates, and block. The only thing done with the press body was having it painted a few years ago.

I also have a smaller one that I lend to students for them to press their medicines as well as occasionally bringing it on the road.

One of the main problems with tincture presses is their price and availability. They are often very expensive, generally costing over $500 and going up from there. And they are difficult to find online or anywhere else

The Role of the Tincture Press

The tincture press is invaluable for pressing (compressing) the plants used when making liquid herbal medicines such as tinctures and glycerites. When pressing a tincture, you can see the color of the liquid change. This represents the constituents that would otherwise be trapped in the plant and not available in the medicine. This increases both the potency of the final tincture as well as capturing more of the medicine that might be lost otherwise.

I understand that many people do not have the money or space for this apparatus. But for those that do, these can be very helpful for getting the most out of your medicine.

There are alternatives such as the potato ricer and apple press, though I find these do not crush and release the constituents of hard plant parts such as seeds and rhizomes as well. But they are inexpensive and easily available.

If you happen to find yourself building one of these…

I know a few people who are interested in purchasing one. In all the years I have been sharing these diagrams, I know only one person who has built a similar functional model. I think many herbalists would be glad to purchase one from a reliable and not-too-expensive source. Keep in mind that shipping them adds a lot to the cost.

Building a Tincture Press

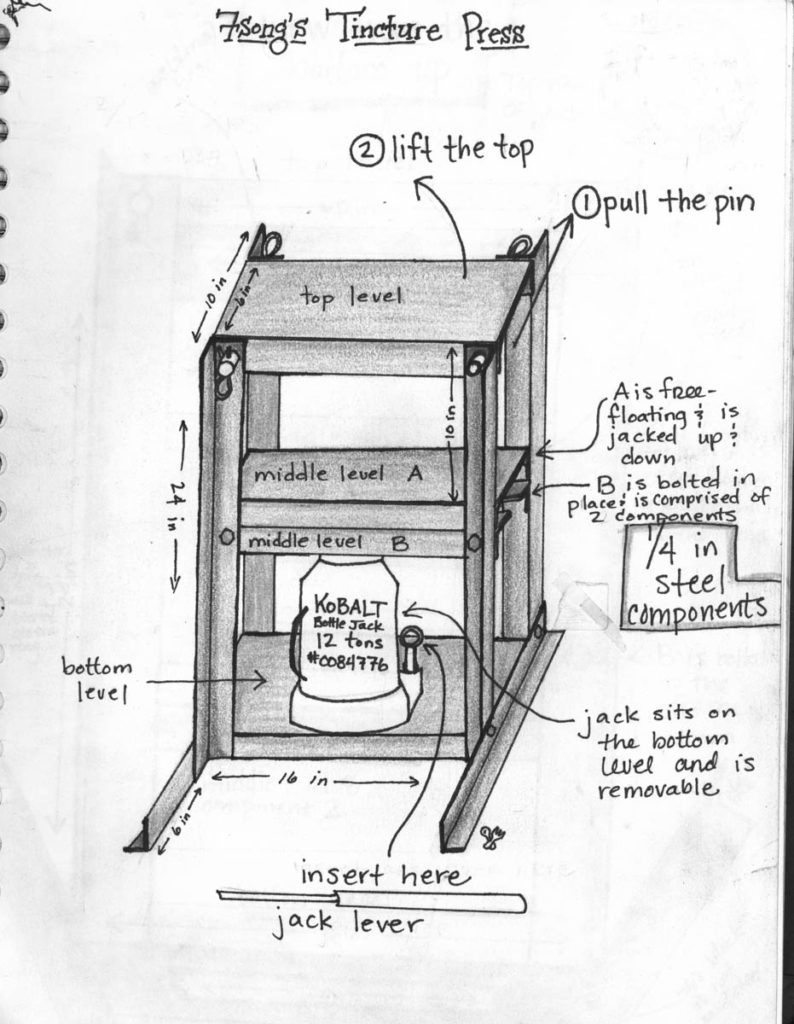

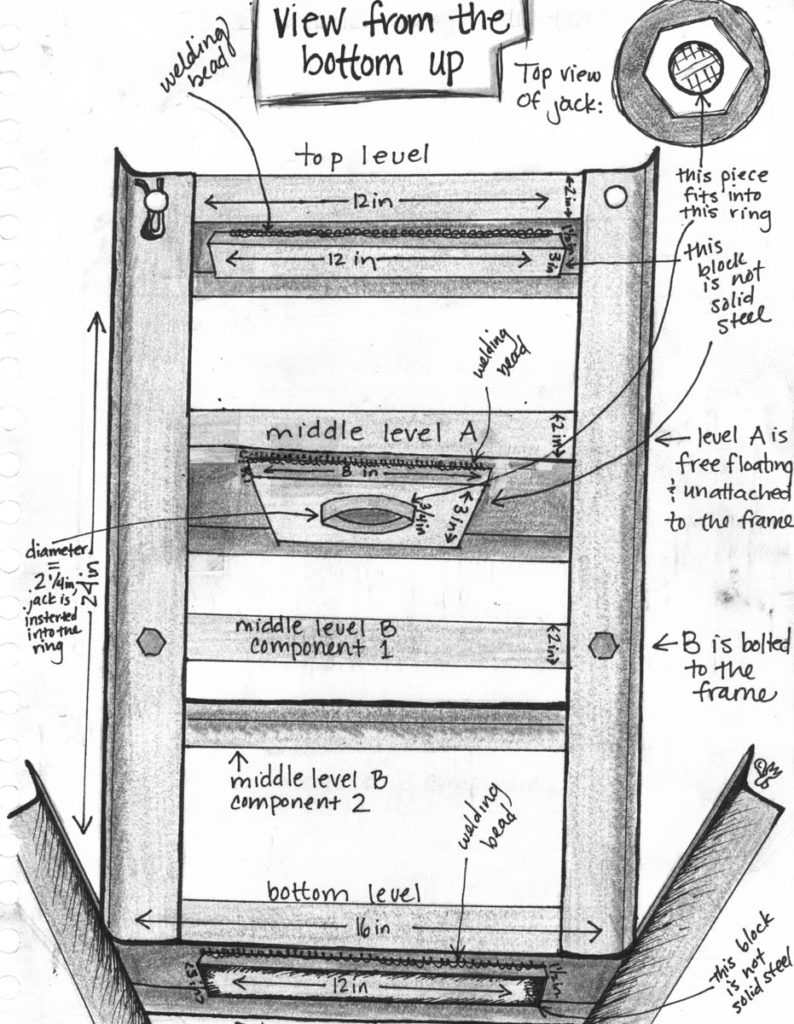

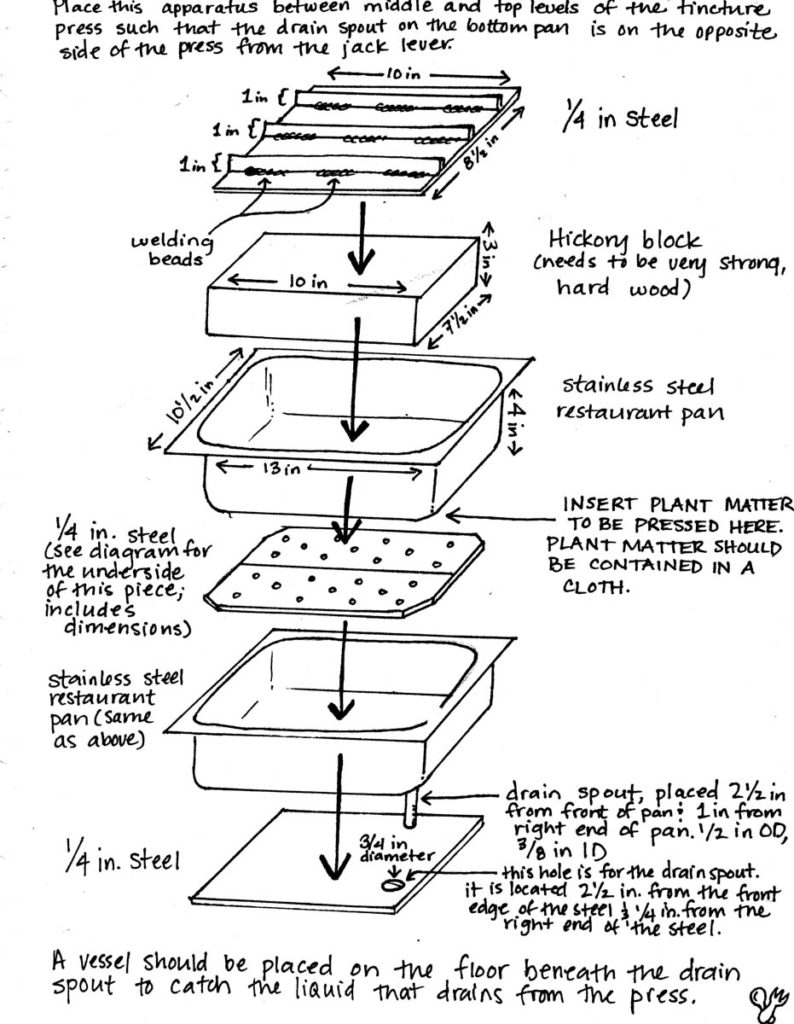

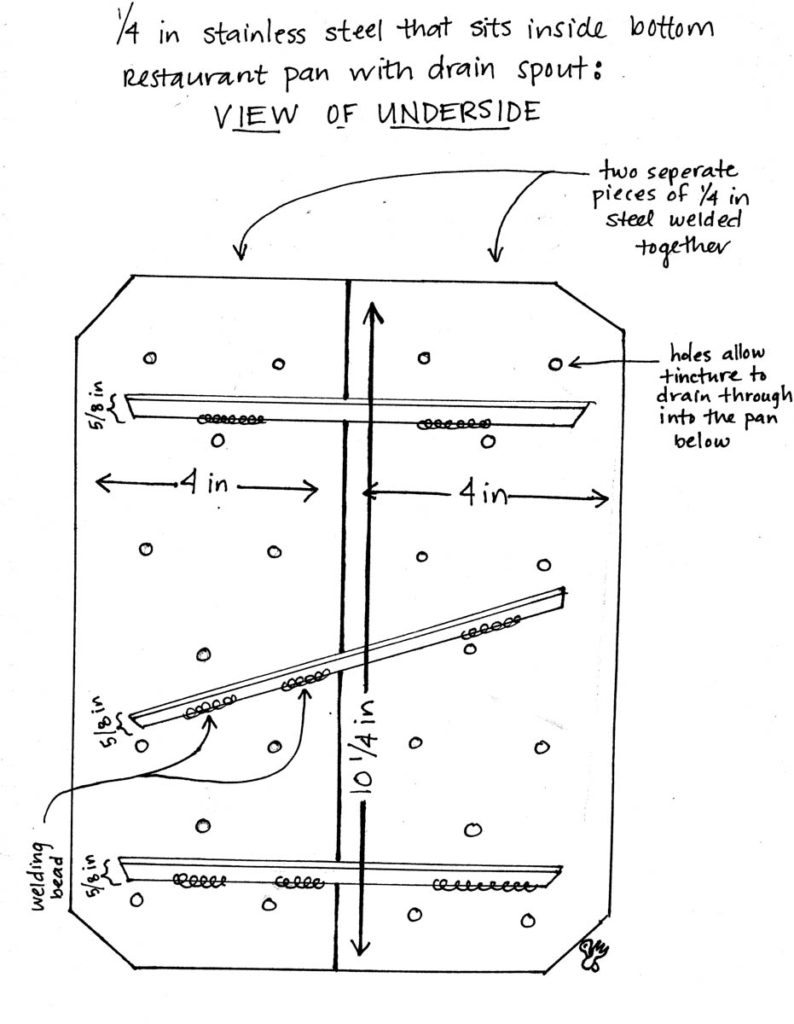

The tincture press schematics were drawn by Cal Janae, a fellow herbalist (thank you again Cal).

I cannot describe the building process, as that is outside my field of expertise (and by ‘outside my field’ I mean 13 galaxies away). But if you are handy and have welding skills, this may be a project for you. The pans are off-the-shelf restaurant supplies, though one of the pans will need a spout welded in. The hydraulic jack is also just a regular car jack (I’ve had to replace this a few times over the years).

Photos of the Tincture Press

The Tincture Press Gallery 1

The Tincture Press Gallery 2

Photo 1- Tincture press with the block inside the pressing pan inside the collecting pan. Photo 2- Tincture press with the block inside the main pan and steel plate on top of the block. Photo 3 & 4- Tincture press fully assembled